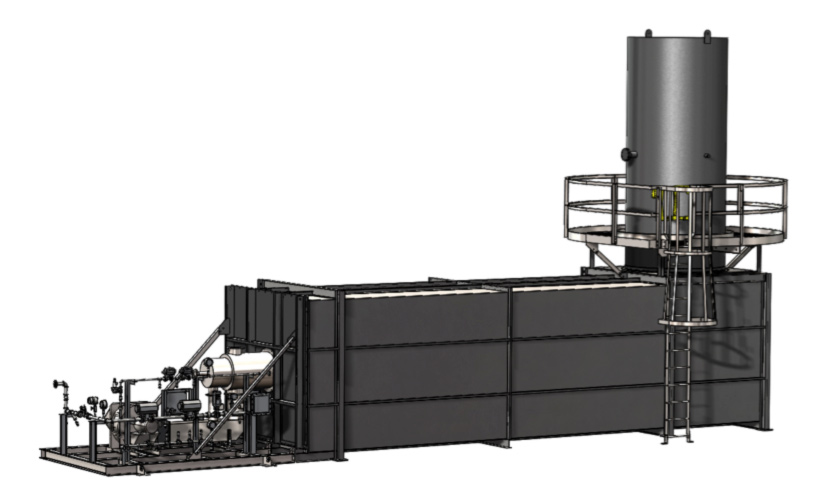

The THM Thermal Oxidizer line is created to provide a simple, robust solution for your incineration needs. Using an array of pre-engineered components, THM can create custom designed packages that meet your specific needs. Our VCU line of thermal oxidizers is designed to handle both liquid and gas waste streams. THM also offers both direct-fired and recuperative designs to meet your project needs.

THERMAL OXIDIZERS

THM evaluates each waste stream composition to ensure that burner stability, waste destruction and NOx reduction are fully optimized. Typical waste streams for our VCU line of thermal oxidizers include

- Acid Gas Residue

- Flash Gas Residue

- Sulfur Compounds (H2S, others)

- Carbon Monoxide

- Hydrocarbons

THM configures the burner and waste injection arrangement to minimize fuel consumption. Burner designs are supplied to allow the waste streams themselves to provide the heat input necessary to produce waste destruction temperatures.

For exothermic reactions/streams, quench air is typically used (and regulated) to maintain temperatures in the proper range for waste destruction. Other quench mediums, such as waste water or inert gas streams, can be used if they are available and make economic sense.

The primary purpose of the thermal oxidizer is to thoroughly destruct all the provided waste streams. A lot of energy is used during this combustion process. Many times, it may make sense to try and recoup some of the created energy using some type of “waste heat recovery” system. This “waste heat” can be used to heat multiple mediums to save energy in another part of the plant. Common waste heat recovery options include:

- Heat medium fluid (i.e. hot oil system)

- Steam

- Air Pre-Heat (for combustion air)

- Waste Pre-Heat (for waste streams to be incinerated)

Each system can be designed and supplied with an associated Burner Management System (BMS) for process control of the unit. THM has pre-engineered BMS packages for the entire range of VCU Thermal Oxidizers, with the ability to customize to meet customer needs. THM has experience with and can work with multiple codes – i.e. NFPA, ATEX, NEMA, IEC, CSA, UL.