We know that when you are working on a project, the heater and thermal oxidizer are only small pieces of the whole puzzle. Your project be a new gas processing plant – which will have several large long-lead items (including the heater and thermal oxidizer) and possibly hundreds of other smaller parts and instruments. Specifying, selecting, and ordering all of these parts can consume a lot of time and effort. And with teams running leaner than ever, time and effort can be a rare commodity.

THM offers a line of auxiliary equipment, as stand-alone equipment or as additions to our heaters and thermal oxidizers, to help reduce the time and effort you need to spend finding equipment for your project. For every heater or thermal oxidizer THM sells, we can also offer the Combustion Management System (often called a Burner Management System - BMS).

For heater packages used in hot oil applications, we can also offer an Oil Circulation Skid (often called a Pump Skid). By purchasing these items with the heater, you can reduce the amount of time and effort needed on your project – from the front end design to the installation. We have also found that in most cases, by purchasing all of this equipment together, you can reduce your overall project costs.

Call or email us today to see how we can best serve you.

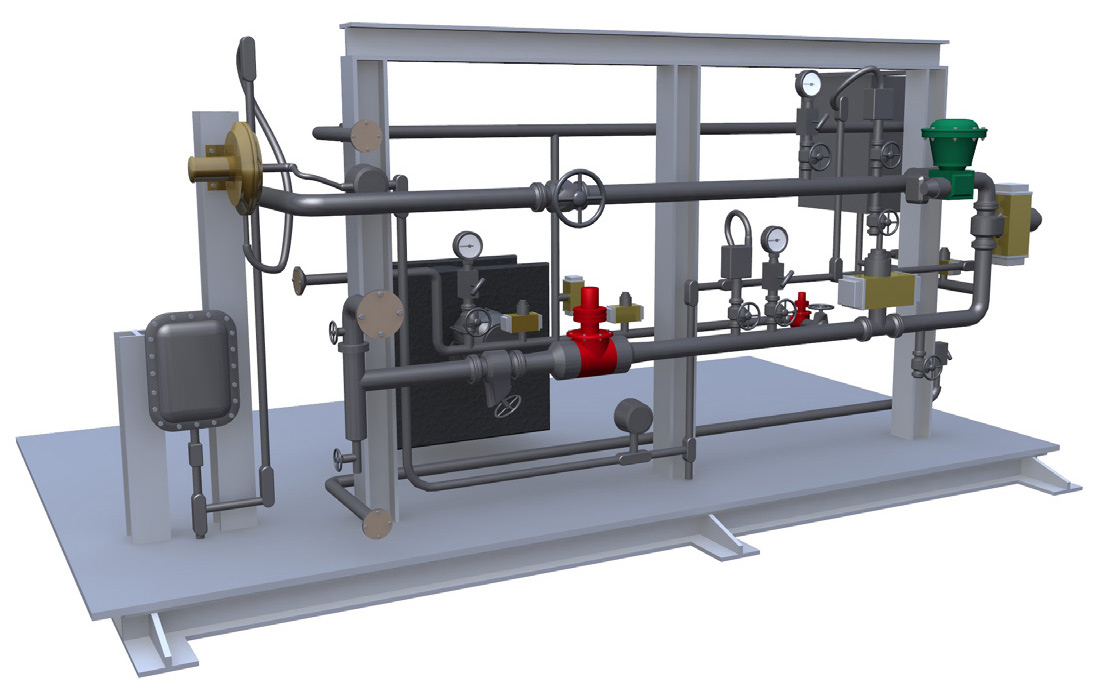

BMS Skid Package

The THM Combustion Management System (CMS) handles all of your typical Burner Management System (BMS) functions, and more. With inlet piping from 1” to 4” NPS, THM has a CMS package to handle heat releases up to 75 MMBtu/hr.

- Gas and oil firing

- Standard packages available, with options to meet customer and project specifications.

- CMS package is skid mounted for quick and easy installation. In most cases, the skid is attached to the heater prior to shipment.

- Pre-commissioning and start-up assistance available for all projects to ensure that your project has a successful start.

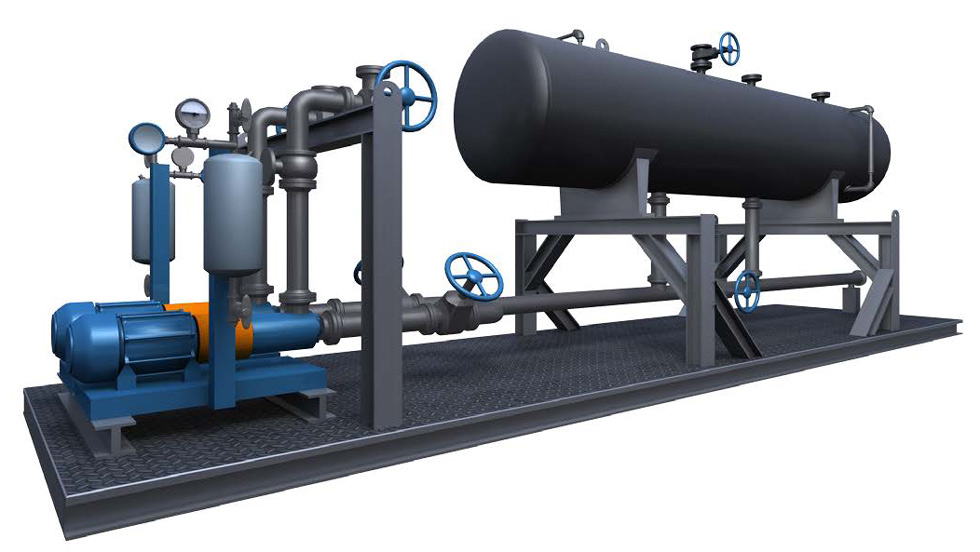

Oil Circulation Skid

Following our SHO heaters and CMS packages, the THM Oil Circulation Skid packages are pre-engineered to provide a fast solution, while still providing the flexibility needed to meet project specific requirements.

- Job specific pumps provided on each skid. These can be designed as twin 100% pumps, or three 50% pumps depending on customer preference.

- Project specific expansion drums integrated onto the skid.

- Options available to meet all customer and project specifications.

Request A Quote